Prepare for the OSHA 10 Module 6 Cranes Exam with confidence! This comprehensive guide delves into the intricate world of crane safety, providing a thorough understanding of crane types, inspections, load capacities, operating procedures, and emergency protocols. Dive in and elevate your knowledge to ensure safe and efficient crane operations.

Types of Cranes

Cranes are versatile and essential pieces of equipment used in various industries for lifting and moving heavy loads. OSHA 10 Module 6 exam covers a comprehensive range of crane types, each with its unique characteristics, applications, and potential hazards.

Mobile Cranes

- Truck-mounted cranes: Mounted on a truck chassis, offering mobility and versatility for various construction and industrial tasks.

- Crawler cranes: Feature a tracked undercarriage, providing stability and off-road capabilities for heavy-lifting operations in rugged terrain.

- Rough-terrain cranes: Designed for uneven surfaces and off-road conditions, combining mobility and lifting capacity.

Tower Cranes

- Self-erecting tower cranes: Can be assembled and disassembled quickly, making them ideal for short-term projects.

- Hammerhead tower cranes: Offer a wide operating radius and high lifting capacities for large-scale construction sites.

- Luffing jib tower cranes: Feature a jib that can be raised or lowered, allowing for precise load placement and operation in confined spaces.

Bridge Cranes, Osha 10 module 6 cranes exam

- Overhead bridge cranes: Suspended from a bridge structure, providing horizontal movement and lifting capabilities within a fixed area.

- Gantry cranes: Similar to overhead cranes, but supported by legs that travel on rails, allowing for movement along a fixed path.

Specialized Cranes

- Boom trucks: Used for utility work, featuring a telescopic boom and a winch for lifting and positioning equipment.

- Forklift cranes: Combine the functionality of a forklift and a crane, offering both lifting and transporting capabilities.

- Telescopic handlers: Versatile machines with a telescopic boom and a variety of attachments for various handling tasks.

Crane Safety Inspections

Regular crane inspections are crucial for accident prevention. They identify potential hazards, ensure compliance with safety regulations, and extend crane lifespan.

Thorough inspections involve:

Visual Examinations

- Inspect structural components for cracks, dents, or corrosion.

- Check wire ropes for fraying, kinks, or broken strands.

- Examine hooks for wear, deformation, or damage.

Functional Testing

- Test crane operation, including hoisting, lowering, and traversing.

- Check brakes, limit switches, and other safety devices.

- Verify load capacities and stability.

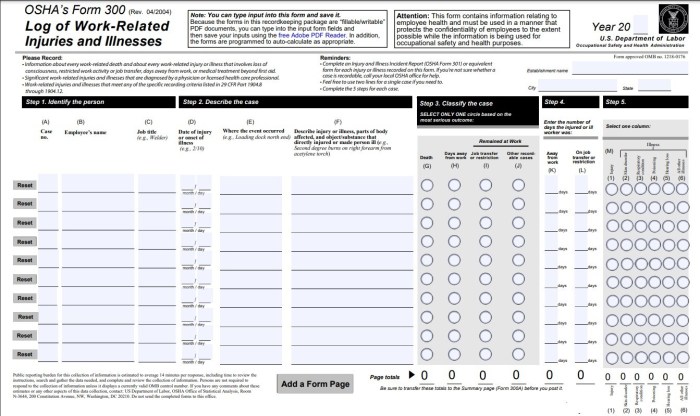

Documentation

- Record inspection findings, including any defects or repairs.

- Keep inspection records for future reference and compliance.

- Use inspection data to identify trends and improve safety programs.

Crane Load Capacities and Stability

A crane’s load capacity and stability are crucial factors in ensuring safe and efficient operation. Various factors influence these aspects, and understanding them is essential for operators and supervisors alike.

Load capacity refers to the maximum weight a crane can safely lift, while stability ensures the crane remains balanced and does not tip over during operation. Both load capacity and stability are affected by several key factors:

Boom Length and Configuration

The length and configuration of the crane’s boom significantly impact its load capacity. Longer booms reduce the crane’s lifting capacity, while shorter booms increase it. Additionally, the boom’s angle and extension also affect load capacity, with higher angles and greater extensions reducing capacity.

Load Radius

The load radius is the horizontal distance between the crane’s center of gravity and the load’s center of gravity. A larger load radius reduces the crane’s load capacity. This is because the farther the load is from the crane’s center of gravity, the greater the overturning moment it creates.

Ground Conditions

The ground conditions where the crane is operating can affect its stability. Soft or uneven ground can reduce the crane’s stability, while firm and level ground provides a more stable base.

Wind Conditions

Wind can create significant forces on a crane, potentially affecting its stability. High wind speeds can reduce the crane’s load capacity and require the operator to take additional precautions, such as reducing the load weight or extending the outriggers.

Calculating Load Capacities

Crane manufacturers provide load charts that indicate the crane’s load capacity at various boom lengths, angles, and radii. To calculate the load capacity for a specific lift, the operator must consider the following factors:

- Boom length and configuration

- Load radius

- Ground conditions

- Wind conditions

Ensuring Crane Stability

In addition to calculating load capacities, operators must also take steps to ensure crane stability. This includes:

- Using outriggers to provide a wider base and increase stability

- Leveling the crane on uneven ground

- Monitoring wind conditions and taking appropriate precautions

- Inspecting the crane regularly for any signs of damage or wear

Crane Operating Procedures

Ensuring the safe operation of cranes is crucial to prevent accidents and injuries. Proper setup, operation, and shutdown procedures must be followed meticulously. Adhering to manufacturer’s instructions and industry best practices is essential for maintaining a safe work environment.

Crane Setup

Before operating a crane, it must be properly set up on a stable surface that can withstand the crane’s weight and load. The crane must be level and all outriggers must be fully extended and set on firm ground. The area around the crane must be clear of obstacles and the ground should be free of any tripping hazards.

Crane Operation

When operating a crane, the operator must be qualified and experienced. The operator must be familiar with the crane’s controls and must be aware of the crane’s load capacity. The operator must also be aware of the surroundings and must be able to safely maneuver the crane without endangering others.

Crane Shutdown

When shutting down a crane, the operator must follow the proper procedures to ensure that the crane is left in a safe condition. The operator must lower the load to the ground and must then turn off the crane’s engine.

The operator must also disengage the crane’s outriggers and must chock the crane’s wheels to prevent it from rolling.

Crane Emergency Procedures: Osha 10 Module 6 Cranes Exam

Crane operations involve potential emergencies that require prompt and appropriate responses to ensure safety. Understanding these emergencies and their corresponding procedures is crucial for crane operators and personnel involved in crane operations.

Load Spills

Load spills can occur due to equipment malfunctions, improper load handling, or environmental factors. In case of a load spill, the operator must:

- Immediately activate the emergency stop button.

- Secure the crane and stabilize the load if possible.

- Notify the supervisor and relevant personnel.

- Evacuate the area and establish a safe perimeter.

- Assess the situation and determine the appropriate course of action.

Equipment Failures

Equipment failures can range from minor malfunctions to catastrophic breakdowns. Upon encountering an equipment failure, the operator must:

- Cease crane operations and secure the load.

- Identify the nature of the failure and assess its severity.

- Contact the maintenance team or supervisor.

- Follow established protocols for reporting and repairing the equipment.

- Prevent unauthorized access to the crane until repairs are complete.

Inclement Weather

Inclement weather, such as high winds, heavy rain, or thunderstorms, can affect crane stability and visibility. In such conditions, the operator must:

- Monitor weather forecasts and avoid operating the crane in adverse weather conditions.

- Secure the crane and load if operations cannot be suspended.

- Follow established procedures for crane shutdown and securing.

- Notify the supervisor and relevant personnel.

Crane Signal Person Qualifications

A crane signal person is responsible for communicating with the crane operator to ensure safe and efficient operation of the crane. They play a critical role in preventing accidents and ensuring the well-being of everyone working in the area.

To be a qualified signal person, individuals must meet certain requirements and undergo specialized training. These include:

Qualifications

- Must be able to clearly and effectively communicate with the crane operator using hand signals or other approved methods.

- Must have a thorough understanding of crane operations, including the crane’s capabilities and limitations.

- Must be able to identify and avoid hazards in the work area.

li>Must be able to work effectively as part of a team.

Training

Signal persons must receive comprehensive training that covers the following topics:

- Crane safety regulations and standards.

- Crane hand signals and other approved methods of communication.

- Crane operation procedures.

- Hazard recognition and avoidance.

- Emergency procedures.

Effective communication is crucial during crane operations. Signal persons must be able to convey clear and concise instructions to the crane operator, ensuring that the crane is operated safely and efficiently. They must also be able to quickly identify and communicate any potential hazards or problems.

Crane Rigging and Load Handling

Proper rigging and load handling techniques are crucial for safe crane operations. Understanding the types of rigging equipment and their proper use is essential to prevent accidents and ensure the safety of workers and the load being handled.

In OSHA 10 Module 6, we delve into the intricacies of crane safety. However, just as we rely on safety measures to protect ourselves physically, some question whether prayer serves as a mental crutch, providing solace in times of need.

Exploring this topic ( is prayer a mental crutch ) can enrich our understanding of both personal and workplace well-being. Returning to OSHA 10 Module 6, it’s imperative to grasp the fundamentals of crane operation to ensure a safe and productive work environment.

Types of Rigging Equipment

- Slings:Flexible connectors made of wire rope, synthetic fibers, or chains, used to attach the load to the crane hook.

- Hooks:Metal hooks used to attach slings or other rigging equipment to the crane hook or the load.

- Shackles:Metal connectors used to join rigging components together, such as slings and hooks.

Safe Use of Rigging Equipment

To ensure safe use of rigging equipment, it is important to:

- Inspect equipment regularly for damage or wear.

- Use the correct type and size of rigging equipment for the load being handled.

- Properly attach rigging equipment to the crane hook and the load.

- Avoid overloading or exceeding the rated capacity of the rigging equipment.

- Protect rigging equipment from sharp edges or heat sources.

Crane Maintenance and Repair

Regular maintenance and repair are crucial for ensuring safe crane operation and preventing accidents. Proper maintenance extends the crane’s lifespan, improves performance, and reduces the risk of breakdowns or malfunctions.

Routine Maintenance Tasks

Conduct regular maintenance tasks to keep cranes in good working condition. These tasks include:

- Inspecting crane components for wear, damage, or corrosion

- Lubricating moving parts

- Tightening bolts and connections

- Checking hydraulic and electrical systems

- Performing load tests

Identifying Potential Problems

During routine maintenance, pay attention to potential problems that may require professional attention. These problems may include:

- Cracks or damage to structural components

- Excessive wear or corrosion on bearings or gears

- Leaks in hydraulic or electrical systems

- Unusual noises or vibrations

- Malfunctioning safety devices

If any of these problems are identified, it is important to contact a qualified crane technician for further inspection and repair.

Essential Questionnaire

What are the different types of cranes covered in the OSHA 10 Module 6 exam?

The exam covers various crane types, including mobile cranes, tower cranes, overhead cranes, gantry cranes, and crawler cranes.

How often should crane inspections be conducted?

Regular crane inspections should be performed daily, weekly, monthly, and annually to ensure safe operation.

What factors determine a crane’s load capacity?

Load capacity depends on factors such as the crane’s design, boom length, and counterweight configuration.